3D scanning and quality management

No test reports or prototype documentation? Not at priomold!

Does your low-volume production have the highest quality requirements and need to be monitored regularly?

priomold's in-house metrology laboratory provides initial sample test reports, serial measurements, 3D scans, IMDS entries and much more using state-of-the-art equipment.

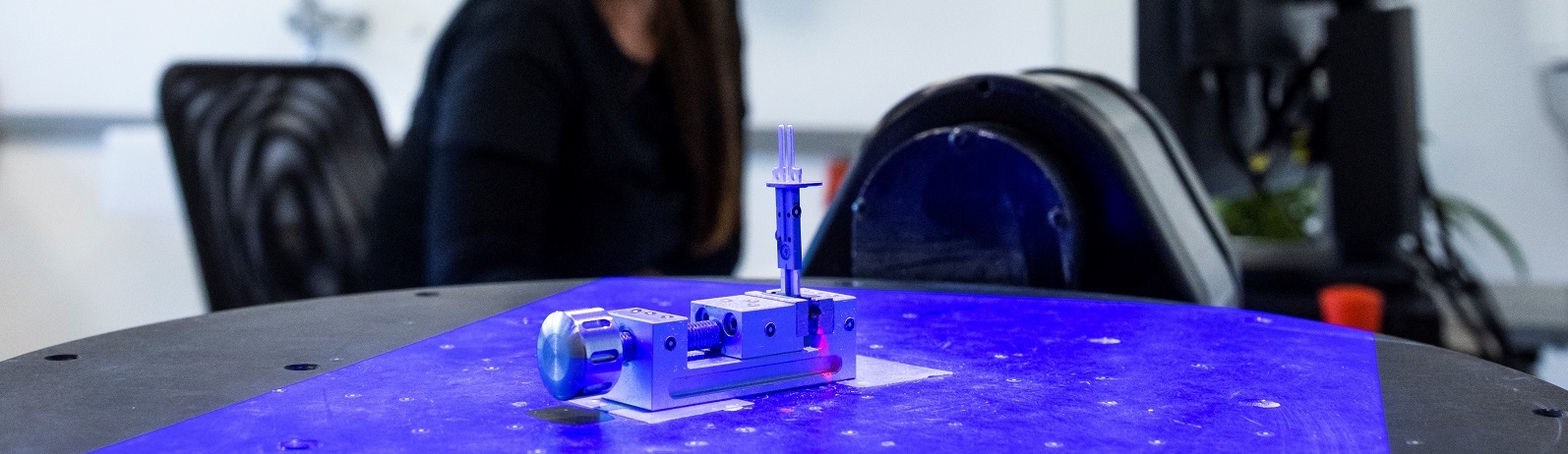

GOM 3D scanning

Fast lead times for prototypes and low-volume production must not end with injection moulding, but must continue in the downstream quality assurance processes.

That's why, since 2020, we have had our own metrology laboratory with a GOM 3D scanner, manual measuring equipment and state-of-the-art software to produce initial sample inspection reports for our customers.

Evaluation options

With priomold, you have a partner who will prepare the measurement results of your plastic parts (injection moulded or additively manufactured) in the way that is best for you.

Quality management services

In addition to the services mentioned above, we can also create IMDS (International Material Data System) entries for you or assist you in creating and dimensioning plastic parts. Effective dimensioning of plastic injection molded parts differs significantly from classical drawing parts (milling, turning, ...). Talk to us about it!

![[Translate to EN:] Abbildung GOM ATOS Capsule Scanner](/fileadmin/user_upload/GOM-priomold-ATOS.jpg)

![[Translate to EN:] Falschfarbendarstellung eines Kunststoffteils](/fileadmin/user_upload/Falschfarben-Darstellung-priomold.jpg)