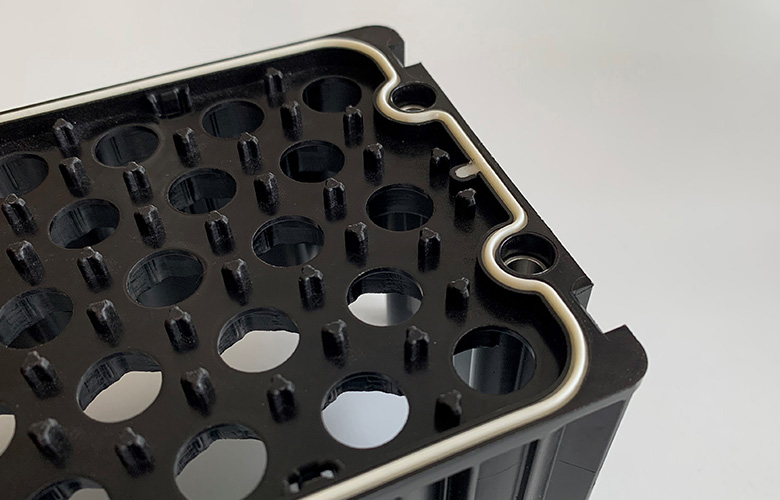

Two-component injection moulding & multi-component injection moulding

priomold offers two-component or multi-component injection moulding, produced using an economical transfer moulding process. This means that 2C injection moulded parts can also be produced economically for prototypes or small quantities. The perfect bond for your product is created by combining different thermoplastics.

Your contact person

Tobias Camek

Sales

t.camek@priomold.de

Phone: +49 (0)7084 97696915

The perfect bond

Two-component injection moulding (2C injection moulding) refers to the overmoulding or injection of an additional, usually soft, plastic material onto a plastic injection moulded part. This is most commonly done by injecting a TPE (thermoplastic elastomer), referred to as a soft component, onto a thermoplastic hard component. The result is a 2C or multi-component injection moulded part.

Cost-effectiveness through transfer moulding

Application and use of multi-component injection moulding

With priomold, you can start small series production after a few weeks instead of months. In addition, it is often more economical than generative processes and 3D printing.