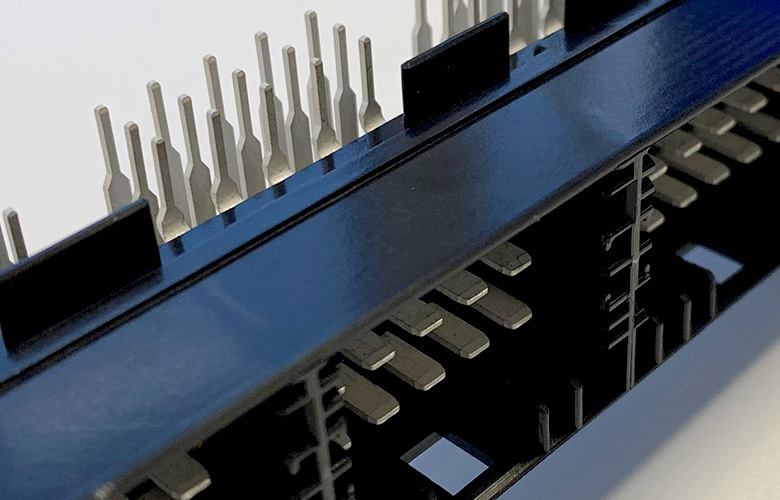

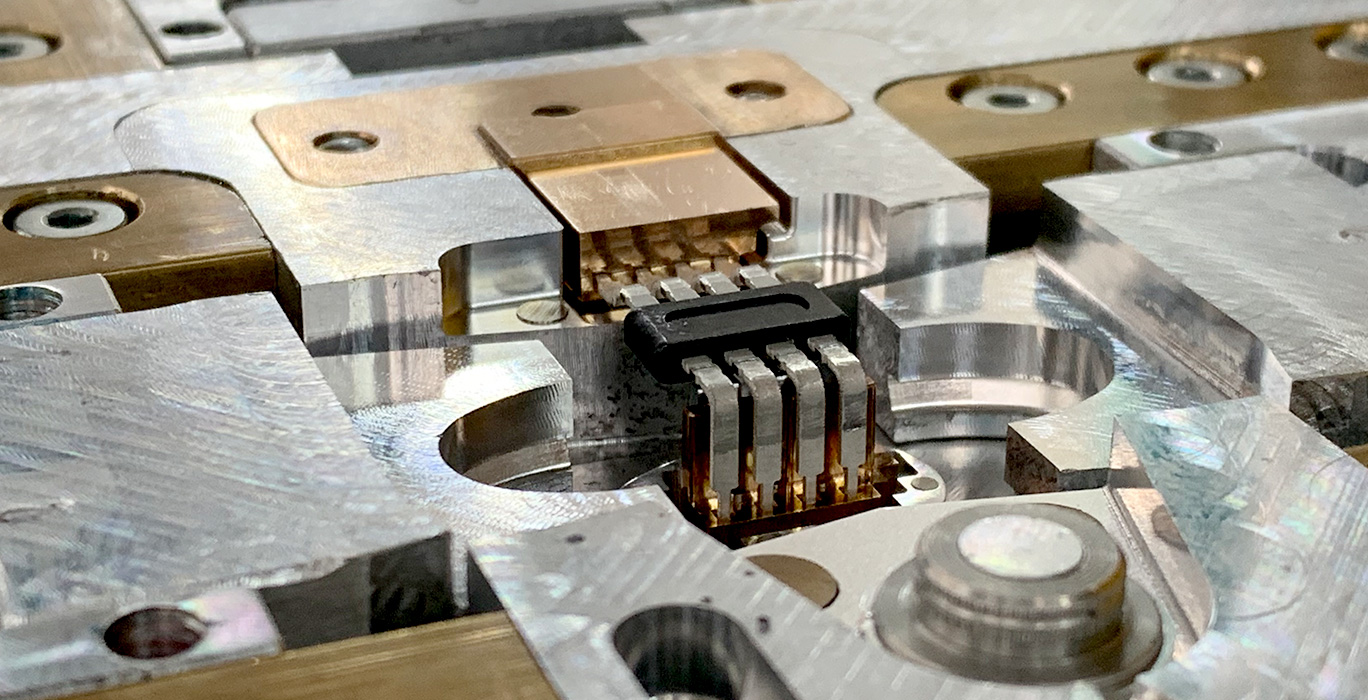

Insert & outsert technology

Do you need complex hybrid components made of plastic with encased threaded bushings, lead frames, plug contacts, busbars or sheet metal?

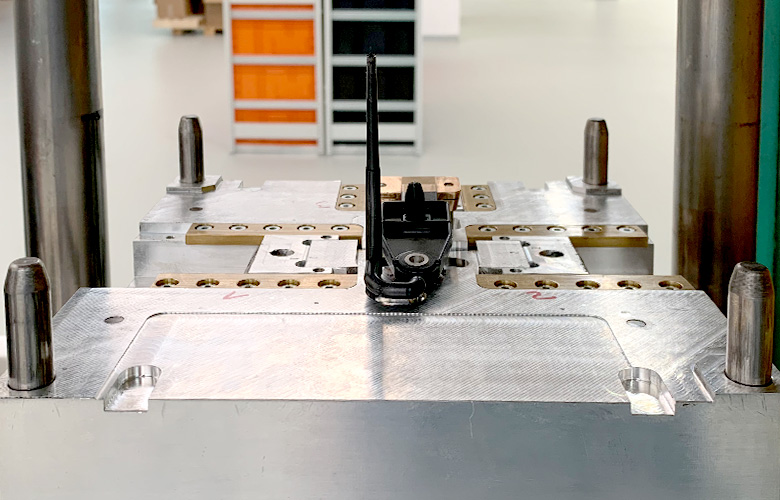

At priomold, inserts are inserted by hand and prototypes and small series are produced on our own vertical and horizontal injection moulding machines.

Your contact person

Tobias Camek

Sales

t.camek@priomold.de

Phone: +49 (0)7084 97696915

Highly complex hybrid components

The overmoulding of metals or other inserts results in a hybrid component made of metal and plastic. The production of highly complex and highly integrated hybrid components is made possible by the insert technology. The focus can be placed on current-carrying inserts or purely mechanical inserts, e.g. threaded bushings.