engineering

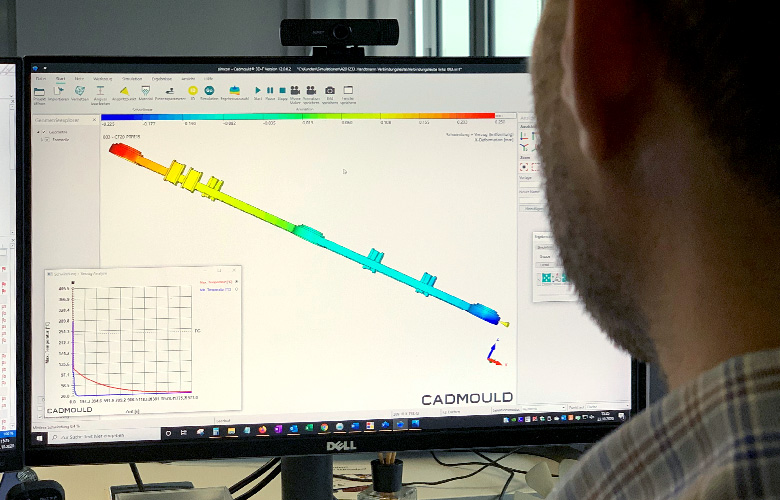

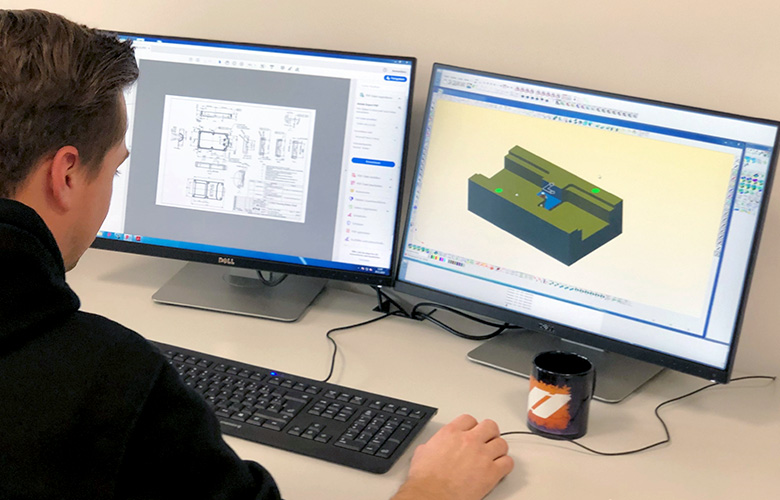

The optimised production of the injection mould as well as the production of the plastic parts result in a win-win situation for you and us: enhanced product quality and high efficiency in production. We pass our expertise onto you and support you in designing your components to be suitable for injection.

Your contact person

Tobias Camek

Sales

t.camek@priomold.de

Phone: +49 (0)7084 97696915

design suitable for injection moulding

The basis for top-quality injection moulding is the plastic part designs being suitable for injection moulding. Mould release angles are just one of many properties that must perfectly match the product’s function and application.

product development to series production

The priomold team will be happy to support you with professional expertise right from the start of product development and supports the development process up to an injection-moulded plastic part being optimised for serial production.