Rapid tooling for prototypes – just like series production, only faster.

Your project deserves speed, precision and quality. priomold delivers functional injection-molded parts in just one week – reliable, accurate and made for your needs.

-

Prototypes from just 1 week: For faster testing, shorter development cycles and visible progress right away.

-

Production-like materials: Realistic functional testing with engineering plastics such as ABS, PA6, PC or TPE.

-

Rapid tooling with aluminum molds: Efficient, precise and repeatable – ideal for fast iterations and low-volume production.

-

Up to 70% cheaper than steel molds: Save budget, accelerate development – without compromising on quality or function.

Why priomold is the right choice for prototype injection molding

Six strong reasons for injection-molded prototypes starting from just 1 part

-

Express manufacturing from just 1 week

Thanks to rapid tooling and in-house production, you receive series-like plastic parts in record time – precise, functional and from a quantity of just 1.

-

Production-like materials and processes

We process engineering plastics such as ABS, PA6, PC or TPE – under series-like conditions. This allows you to test realistically and shorten your time-to-market.

-

Everything under one roof

Design, toolmaking, injection molding and quality assurance – all closely integrated. The result: short communication paths, clear responsibilities and no time lost.

-

Flexibility for changes – without delay

Iterations, design adjustments or new quantities can be quickly integrated. You stay in control and maintain your development speed.

-

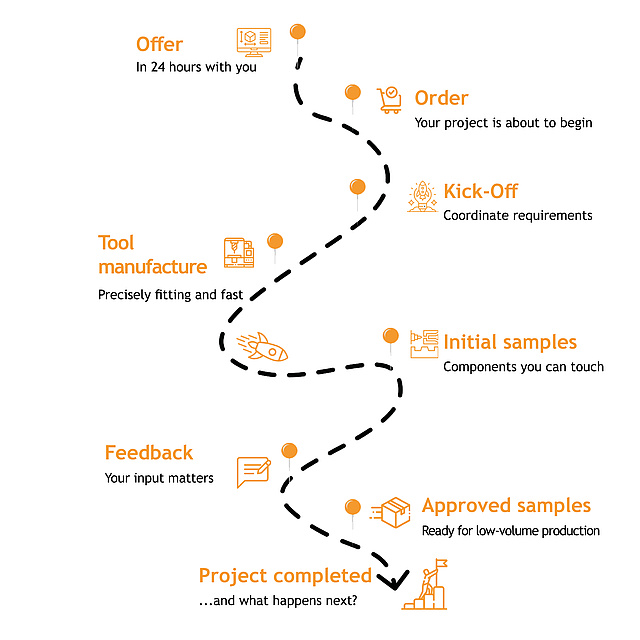

Transparent processes & measurable quality

You always know which step is in progress, when your parts will be delivered – and how precise they are. Every part undergoes an internal quality check with state-of-the-art measuring technology.

-

Technical experts at eye level

At priomold, you talk to people who understand your language. Your dedicated project partner knows the technical requirements and thinks ahead – from the first data set to the start of series production.

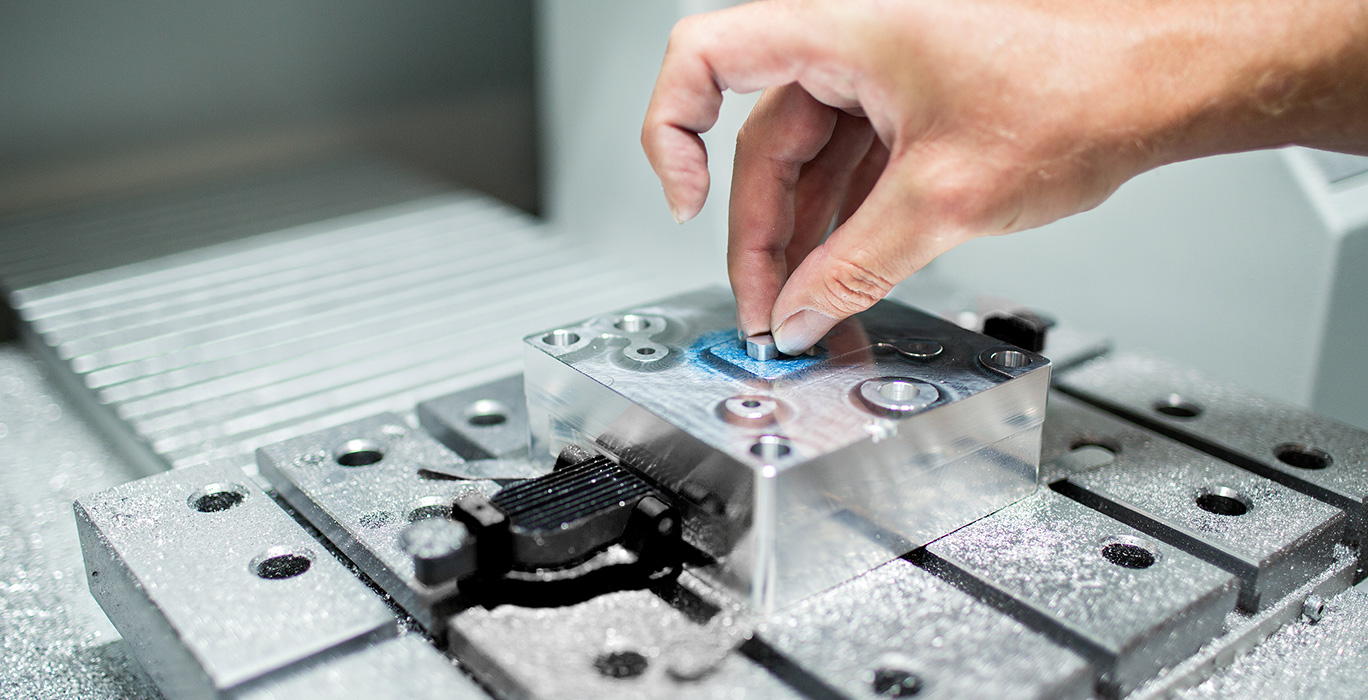

Rapid tooling with aluminum molds

Your path to functional parts – with priomold as your partner in prototype injection molding

Your dedicated support for prototype injection molding projects

Tom Green

Telefon: +49 7084 976969 114

t.green@priomold.de

“Looking ahead to series production with your prototype mold? I’ll make sure we optimize for repeatability and cycle time together.”