Rapid tooling – prototype injection moulding

Are you looking for high-quality prototypes made of serial material with form and function? You want your prototype injection moulding tool to be up to 70 percent cheaper than a conventional steel tool?

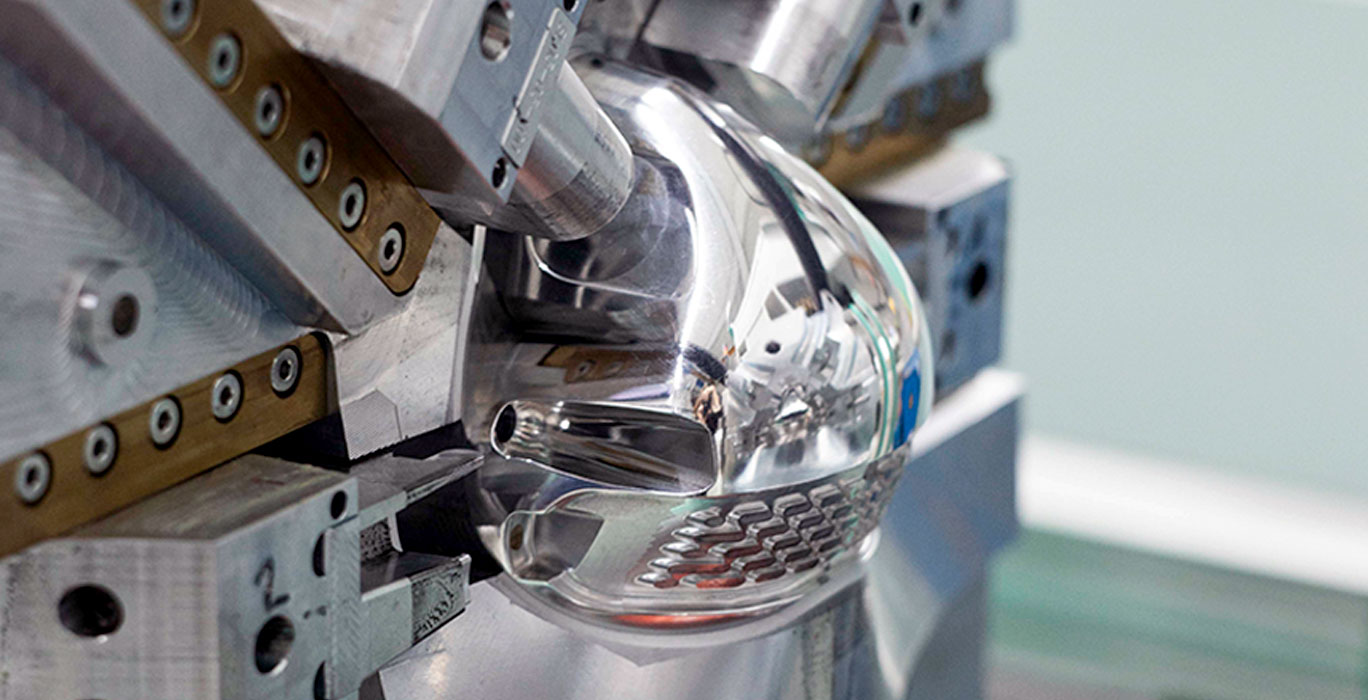

Rapid tooling is a modern prototyping method for the production of prototypes by injection moulding.

Your contact person

Tobias Camek

Sales

t.camek@priomold.de

Phone: +49 (0)7084 97696915

Injection moulding – the prototyping process

A prototype should not only look good, but also reflect the function and characteristics of the later series product. That’s why prototypes using injection moulding are the first choice for your project.

Prototype process with unique material variety

Delivery time from 1 week

Thanks to our ultra-modern and automated tool shop specialised in the production of tool inserts made of high-strength aluminium, we can offer delivery times starting from 1 week for new products.