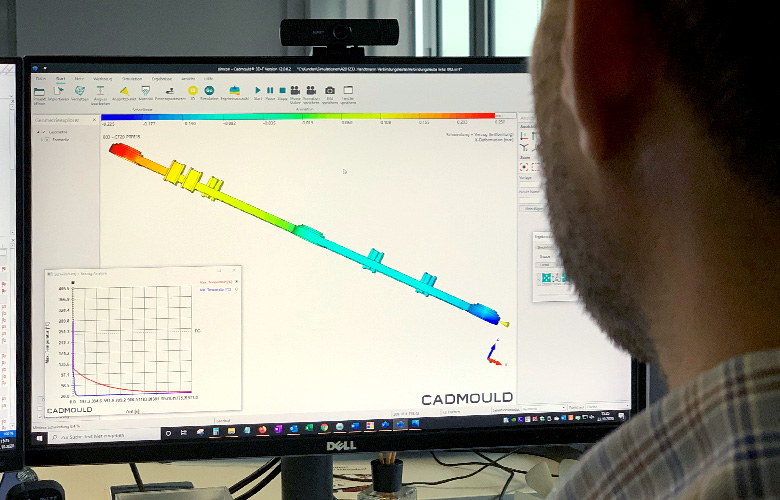

priomold GmbH now offers rapid, data-driven feasibility analysis for injection-molded parts in the prototype phase. Within just 60 minutes, developers receive clear feedback on whether their part geometry is suitable for injection molding — including a filling simulation, assessment of critical features, and DFM (Design for Manufacturability) commentary.

Minimizing technical risk before toolmaking begins

In early development, the question often arises: Can this part actually be injection molded as designed?

With the QuickDFM service, priomold provides detailed technical insight that supports critical decisions — from design freeze and mold release to the transition into series production. Based on STEP-format CAD data, each analysis is performed by priomold’s experienced team, specializing in tool-based prototype production.

The following aspects are evaluated:

- Flow behavior and sprue location

- Demoldability (e.g. undercuts, draft angles)

- Wall thickness profile, ribs and edge transitions

- Potential weld lines, air entrapment, hotspots

Online upload module with rapid turnaround

Designers can upload their STEP files and specify material preferences or project constraints via an online form. The analysis is completed within 60 minutes during business hours.

Each result includes:

- A visually prepared filling simulation

- Technical evaluation of the part's injection moldability

- Follow-up queries from the engineering team if necessary

The analysis is grounded in priomold’s extensive project experience with aluminum prototype tools — including cycle-appropriate temperature control and process-aware evaluation. By identifying risks early, teams can avoid delays or quality issues later in the project. QuickDFM enables informed decisions during the most critical phase of product development.

25.07.2025

Ellen Wilhelm

Marketing manager

e.wilhelm@priomold.de

Phone: +49 7084 976969 250